Imagine how meticulously a robotic arm would assemble fragile circuits, with every step carried out with unfailing accuracy. Or think about how a CNC machine can effortlessly carve a complicated shape as the cutting tool follows a precise route. What makes these controlled motion achievements possible? The optical rotary encoder is one of the most important sensing technologies that frequently holds the key to the solution.

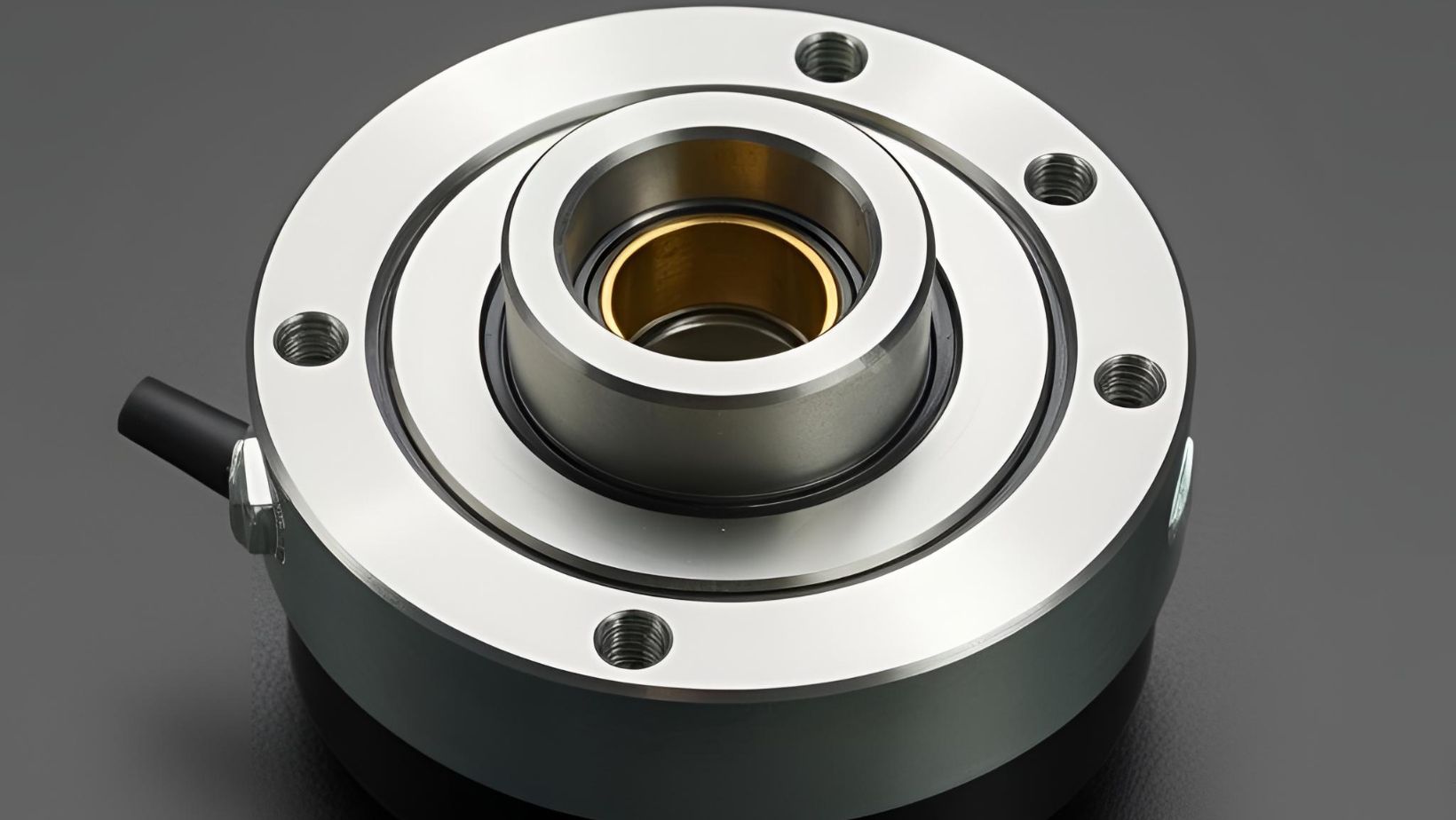

An optical rotary encoder is an electromechanical device that translates rotational motion into digital signals. Think of it as a highly accurate digital translator for movement, providing precise feedback on the angular position, speed, and even direction of a rotating shaft. Control systems then utilize this invaluable information to ensure movements are executed accurately and efficiently.

Renowned manufacturers like ELTRA Encoders exemplify the advanced engineering behind these components, offering a wide range of high-performance optical rotary encoders tailored to diverse industrial needs.

The widespread adoption of optical rotary encoders stems from their inherent advantages. They offer exceptional accuracy and reliability in measuring rotational displacement. Their versatility allows them to be integrated into various applications, from delicate scientific instruments to heavy-duty industrial machinery, making them a cornerstone of modern automation and control systems.

The Fundamentals of Optical Rotary Encoders

At its core, an optical rotary encoder comprises a few key elements: a light source (typically an LED), a precisely patterned code disk featuring opaque and transparent segments, photodetectors that sense light, and signal processing electronics. The fundamental principle of operation involves the rotation of the code disk, interrupting the light beam emitted by the source. This interruption generates a sequence of light pulses, which are then detected by the photodetectors and converted into digital signals, typically square wave pulses. These output signals commonly include A and B quadrature signals, two pulse trains slightly out of phase that enable the determination of both rotational speed and direction. For absolute position referencing in incremental encoders, an index pulse (a Z or zero channel) is frequently present, offering one pulse each rotation.

Types of Optical Rotary Encoders

Two main categories can be used to broadly classify optical rotary encoders, each with unique operational traits and applicability:

Incremental Encoders

- Provide relative position information by generating pulses as the shaft rotates. The position is determined by counting these pulses from a defined reference point.

- A homing or indexing procedure is required upon startup to establish an absolute zero position, as the encoder itself does not inherently provide this information.

- Offer advantages such as simplicity in design and lower cost compared to absolute encoders.

- A primary disadvantage is the potential for loss of position information during a power interruption, necessitating re-initialization.

- Common applications include scenarios where relative motion and speed measurement are paramount, such as in motor feedback, conveyor systems, and basic motion control.

Absolute Encoders

- Generate a unique digital code corresponding to each discrete angular position of the shaft, providing absolute position information immediately upon power-up without needing a reference movement.

- Achieve this by using more intricate code disks with multiple concentric tracks. Each track features a specific pattern of opaque and transparent segments, which are read by various photodetectors to produce a unique binary or Gray code representing the absolute angle.

- Offer significant advantages, including directly determining absolute position and eliminating the homing requirement.

- Typically exhibit higher complexity and cost due to the sophisticated code disk design and increased number of sensing elements.

- Applications demanding precise and immediate absolute position feedback, such as in robotics, CNC machinery, and high-accuracy positioning systems, frequently utilize absolute encoders.

Advantages and Disadvantages of Optical Rotary Encoders

Optical rotary encoders offer a compelling set of benefits for precise motion sensing, but also present certain limitations to consider for specific applications.

Advantages

- High Accuracy and Resolution: Optical encoders can provide precise measurements and achieve high resolutions, allowing for fine control and accurate positioning.

- Non-Contact Measurement: The fundamental operating principle relies on light detection, eliminating physical contact between the sensing components and the rotating disk. This non-contact nature significantly reduces mechanical wear and tear, contributing to a longer lifespan and improved reliability.

- High Operating Speeds: Optical encoders can operate effectively at high rotational speeds, making them suitable for dynamic applications.

- Good Frequency Response: They exhibit a good ability to accurately track rapid changes in rotational speed, which is crucial for applications requiring responsive feedback.

- Immunity to Magnetic Interference: Unlike magnetic encoders, optical encoders are inherently immune to electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring reliable operation in electrically noisy environments.

- Relatively Compact Size: Compared to other encoders, optical encoders can be designed with a relatively small footprint, facilitating integration into space-constrained systems.

Disadvantages

- Sensitivity to Contamination: The optical components can be susceptible to performance degradation or failure due to contaminants such as dust, oil, and moisture, which can obstruct the light path.

- Potential for Damage from Shock and Vibration: While ruggedized versions are available, standard optical encoders can be more vulnerable to damage from significant mechanical shock and vibration than robust encoder technologies.

- Cost Considerations: Optical encoders, particularly absolute encoders with their complex designs, can be more expensive than some alternative encoder technologies, such as resistive or basic magnetic encoders.

Applications of Optical Rotary Encoders

The precision and reliability offered by optical rotary encoders have led to their widespread integration across a diverse spectrum of industries and applications, enabling precise motion control and feedback in numerous critical systems.

Industrial Automation

Optical encoders are fundamental in robotics for precise joint articulation and end-effector positioning, in CNC machinery for accurate tool path control and spindle speed regulation, within packaging equipment for synchronized material handling and indexing, and in various material handling systems for precise conveyor belt speed and product placement.

Motion Control

They provide precise position and velocity data for closed-loop control systems, making them essential feedback components in servo and stepper motors. Their integration into general feedback systems ensures precise control over various mechanical movements.

Medical Equipment

In the medical field, optical encoders contribute to the accuracy of critical diagnostic and therapeutic equipment such as MRI and CT scanners by precisely controlling patient table movement and gantry rotation. They are also vital in surgical robots to enable minimally invasive procedures with high precision.

Aerospace and Defense

High-reliability optical encoders are employed in demanding aerospace and defense applications, including the precise positioning of radar systems, the control of flight control surfaces on aircraft, and within navigation systems for accurate orientation and movement tracking.

Renewable Energy

Optical encoders play a role in optimizing the efficiency of wind turbines by precisely controlling blade pitch and yaw, and in solar panel tracking systems by accurately orienting the panels to maximize sunlight capture.

Consumer Electronics

While often unseen, optical encoders are utilized in various consumer electronics, such as printers for precise paper feed and print head positioning, scanners for accurate image capture, and even legacy optical drives for precise disc rotation and read head positioning.

Scientific Instrumentation

The need for precise measurement and control in laboratory equipment and large-scale instruments like telescopes makes optical encoders indispensable for accurate positioning and tracking.

In conclusion, advanced electro-mechanical systems known as optical rotary encoders transform rotational motion into accurate digital information. Their function is based on a patterned code disk interrupting a light beam, which is then recognized and processed to provide direction, speed, and position information. The two main types of these encoders are absolute encoders, which offer distinct digital codes for every angular position, and incremental encoders, which provide relative position feedback. The intrinsic benefits of optical rotary encoders—such as their high accuracy and resolution, non-contact operation, high speed capabilities, immunity to magnetic interference, and comparatively small size – propel their widespread use.

Looking ahead, the field of optical encoder technology continues to evolve. Trends include the development of even higher resolution encoders, miniaturization for integration into increasingly smaller devices, and incorporating more robust designs to withstand harsh environmental conditions. Advancements in communication protocols and digital interfaces also enhance their integration into complex control systems.

Optical rotary encoders are a vital component of contemporary technology, offering the motion feedback required for innumerable automated procedures, high-precision devices, and sophisticated gear in a wide range of sectors. Their precision, dependability, and adaptability guarantee their ongoing significance in promoting innovation and permitting ever-more-advanced degrees of control.